trackbot

Solutions for a better workenvironment

We believe that today’s work environment is changing

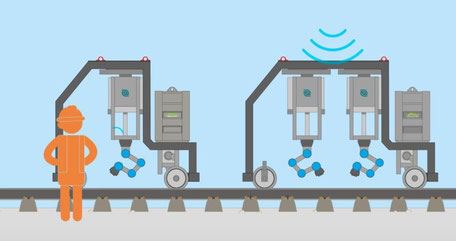

Together with AMT Group, No Man Trackwork develops and manufactures intelligent machines that take physical and monotonous labor off your hands. Thanks to smart technology, TRACKBOT works autonomously and quality is ensured. This innovative multipurpose machine is the new rail colleague in the rail construction industry.

SAFE

The TRACKBOT ensures no to less to no exposure of employees to:

• Physically demanding work (lifting, stooping)

• Irregular working hours (disrupted biorhythms and social life)

• Noxious fumes (Quartz dust, machine exhaust)

• Vibrations due to operation of machinery

• Being in the danger zone of the work

EFFICIENT

• Available 24/7

• Production increase and predictability

• Quality Data Logging

• Reduced environmental impact through

the 100% Electric powertrain

• Savings and more efficient use of employees

• Ability to connect to other systems

(GPS, planning systems, process control)

AUTONOMOUS

TRACKBOT is designed to be rapidly deployable and perform work completely autonomously. The present machine is capable of independently detecting rail fasteners, loosening or tightening them, and thereby positioning the spring.

FLEXIBLE

In the future, the machine can be equipped with other types of robots, grippers and infeed and outfeed belts in order to carry out other work. For example, installing rail dampers, screws and other components. The laying of rolls for the tensioning of rails is also possible.

TRACKBOT is electrically powered and can be powered by a 100% Electric battery pack, cable or generator.

MODULAR TECHNOLOGY

TRACKBOT has a modular design, which means that expansion of the machine is one of the options. Coupling multiple machines together is also possible to increase production. Using an LCD screen and internet connection, the machine is controlled and read out. Data, such as tightening torque, spring position or missing parts, are logged.

CONTINOUSLY IN DEVELOPMENT

We develop and produce these advanced solutions together with international customers, Dutch specialists and producers. As a result, you can count on systems that meet all applicable safety requirements, accurate service and continuous development.